How B-Side Customers Can Achieve a 35% Cost Reduction by Leveraging Guizhou-Zhejiang Production Regions. Global matcha buyers are facing a double squeeze, with high-end Japanese matcha prices soaring 20% and the risk of pesticide residue overload surging in Southeast Asia’s low-end products.

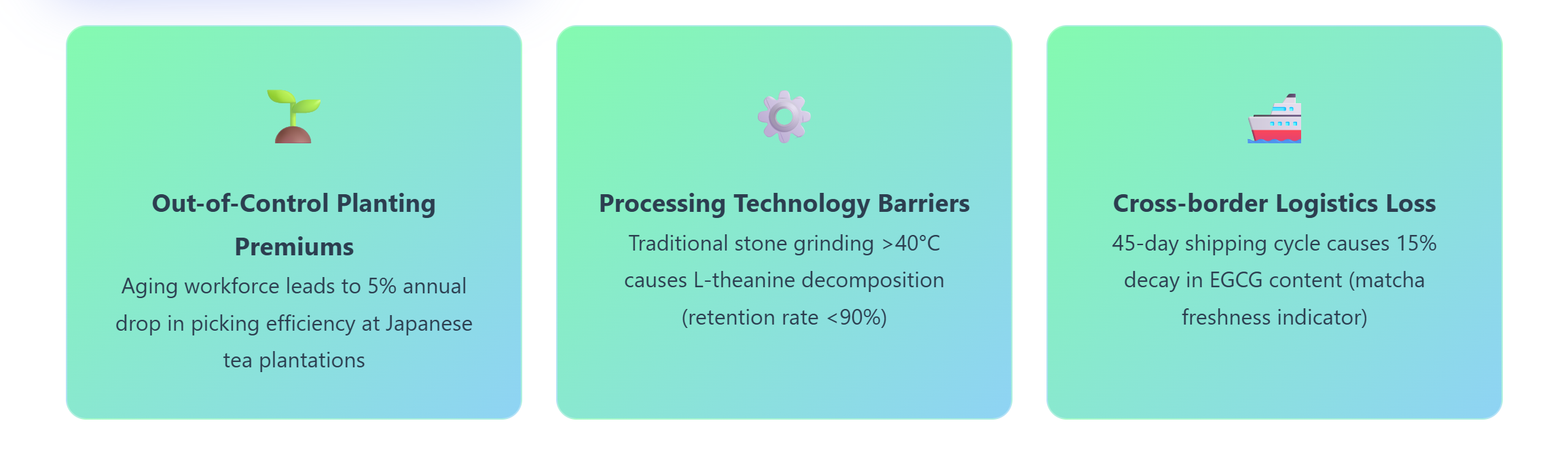

Three Major Cost Black Holes in Traditional Matcha Supply Chain

How Guizhou Production Region Penetrates the Price Ceiling

Processing Technology Breakthrough: Three Steps to Lock Active Ingredients

1. Pre-cooling Treatment

-18°C Freeze-drying to Lock Freshness: Guizhou tea leaves enter vacuum freeze-drying warehouse within 1 hour after picking. Water removal at -18°C (vs Japan’s hot air drying ≥60°C) prevents L-theanine thermal degradation from source. Post freeze-drying water content ≤5%, reducing grinding resistance by 40%.

2. Liquid Nitrogen Instant Cooling

-5°C Constant Temperature Environment: Domestic equipment injects liquid nitrogen aerosol (-196°C) into grinding chamber, stabilizing internal temperature at -5°C. Zirconia ceramic beads (0.3mm diameter) replace traditional stone grinding, reducing friction heat by 72%.

3. Particle Classification & Airflow Sorting

Post-grinding powder sorted via -10°C inert airflow. >15μm particles return for re-grinding (Japan lacks this cycle). 5-10μm ultra-fine powder collected via cyclone collector, temperature maintained <10°C throughout.

Key Performance Comparison: Domestic vs Japanese Equipment

| Indicator | Domestic 3rd Generation Equipment | Japanese Mainstream Equipment | Advantage Difference |

|---|---|---|---|

| Grinding Temperature | -5°C~10°C constant temperature | 35°C~45°C fluctuation | ↓45°C |

| Grinding Time | 8 minutes/batch | 30 minutes/batch | ↓73% |

| L-theanine Retention Rate | 92.3% (JNU testing) | 89.7% (JAS certified data) | ↑2.6% |

| Unit Energy Consumption | 0.8 kW·h/kg | 2.1 kW·h/kg | ↓62% |

Scientific Basis: L-theanine degradation rate reaches 1.2% per 10 minutes in >30°C environments (cited from Food Chemistry Vol.358). Domestic equipment compresses thermal damage window to 1/4 of Japanese processes through low temperature + short time processing.

🚀 Case Study Success

German organic food brand Grüne Kraft shifted matcha powder procurement from Uji to Guizhou, reducing per-kilogram procurement cost from €385 to €249 (35% cost reduction). Theanine content increased from 2.1% to 2.4%, with shipping cycle shortened to 22 days (Shanghai port direct to Hamburg).

Logistics Efficiency: Zhejiang Ports’ Strategic Pivot Role

Zhejiang Advantages

Raw tea entering Ningbo Free Trade Zone for grinding exempted from 13% VAT.

Three direct flights weekly to US West Coast, container temperature maintained at 4°C±1.

Blockchain technology enables full temperature and humidity monitoring from tea garden to filling

Three Steps to Obtain Cost Optimization Benefits

Select Guizhou tea gardens with dual qualifications: China Organic Certification (CNAS) + Japan JAS Certification.

Contract Processing: Fresh tea leaves shipped directly to Zhejiang Free Trade Zone, avoiding raw material import tax.

Customized Grading: Gradient pricing according to EGCG/Theanine content (price difference per grade <8%).

Use letter of credit pledging to obtain supply chain finance, improving capital turnover efficiency by 2.3 times.

When matcha supply chains meet China Smart Manufacturing, quality and cost are no longer an either/or choice. The highland genes of Guizhou’s tea plantations and the technological empowerment of Zhejiang’s industrial clusters are driving the reconstruction of the global matcha value chain.

What we provide is not only matcha raw materials, but also the strategic leverage to reshape your product competitiveness.

Visit our website and get it touch

www.yshherb.com